Reviewed : BeadMaster - Spotbead

A common dilemma during the first fix wiring of down lights - do you ask the plasterer to bring the cables through the plasterboard, or leave them above and try to find them later? Either way, someone's job is going to be more difficult.

By Gary Hayers & Joe Robinson

Wednesday 17th July 2019

SHARE IT

This is going to get messy

The plasterer has to work around a mass of holes and wires, or the electrician needs to remember where to cut the holes during the second fix, praying cables haven't been moved. At the end of this, if the ceiling looks a mess, don't worry the painter and decorator can sort it.

Video review - Gary and Joe dust off their plastering skills

To preserve peace and on-site harmony, plasterer Pete Carter, developed the spotlight bead. It's one of those eureka products which poses the question, why haven't we always done it this way?

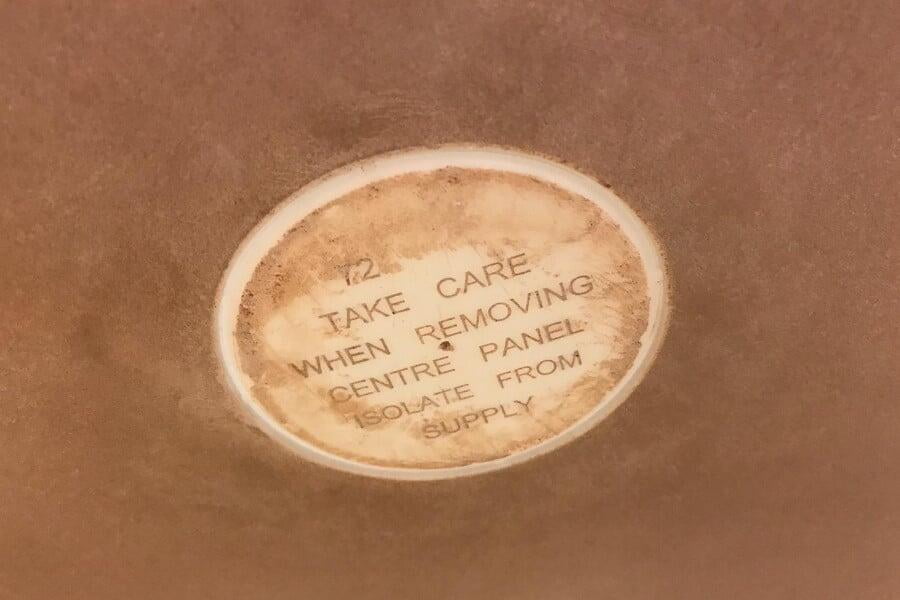

The concept is straight forward; the spotlight bead is a cover which fixes over the downlight hole and gets plastered over. During the second fix, the plastic centre is cut out, downlight connected and pushed into the neat hole.

Why else should you use a Spotbead?

- Many of the higher-end downlights have narrow mounting flanges to minimise ceiling dimensions, resulting in a lower tolerance to cover the mounting hole. Spotbead creates a cleaner neater hole with less chance of collapse when the fixing springs attach makes installation much easier.

- The final choice of downlight size can be decided later in the project. The cut-out on the Spotbead allows for downlight sizes of between 72mm down to 57mm or less if fire-rated downlights aren't required.

- Cables can be stripped back, terminated and tested before plastering, then left behind the Spotbead ready for second fix wiring.

- The solid hole edge reduces the risk of ceiling damage during testing and maintenance over the life of the installation.

The only remaining dilemma is who should be fitting the Spotbead? Is this a product for electricians to install or plasterers? The answer is probably both; it just depends upon the project phasing. To eliminate finger-pointing, we'd suggest that architects and project managers should be including Spotbeads in project documents and specifications.

Our verdict

It's rare to find a product in which many different trades are a winner. Spotbead makes everyone's job much easier. The ultimate winner is the end client who ends up with a perfect ceiling finish.

SHARE IT

Got a question about this product?