Designing and installing LED strip

LED strip or LED tape is literally one of the most flexible light sources, used to light everything from furniture and bathrooms to gardens and building facades. With a vast choice of colours, light output and power supply options from many different suppliers, it's easy to get confused. In this series, we explore everything to do with LED strips to help you create great lighting results and more reliable installations.

by Gordon Routledge

Monday 27th July 2020

SHARE IT

Why use LED strip?

The lighting effect by using LED strip is limited only by the creativity of the designer and installer. Being flexible LED strip can be cut to fit exact measurements and shaped to almost any feature. LED strip can be a primary light source or used to highlight decorative features. LED strip is suitable for integration within architectural elements to create indirect lighting, or housed in lightboxes are extruded profiles to create unique stand-alone lighting features.

VIDEO - LED Strip series introduction

Getting it right.

A successful LED strip lighting project relies upon selecting the right materials and carefully matching them to the application. An LED strip intended for lighting inside a wardrobe and occasional use is vastly different from a hotel entrance used all day.

Understanding the LED strip specification sheet

Understanding the LED strip specification sheet

At first, a specification sheet for LED strips can be confusing as they are a mixture of lighting, electronic and electrical terminology. Understanding the different parameters is essential to choose the correct LED strip for an application and be able to compare one manufacturer with another.

Higher specification LED strips generally have more information, and lower cost ones often leave out critical information for a good reason, you may learn why after installation.

LED Pitch

LED Pitch

How far apart the LEDs are along the strip. If you can directly see the LED strip in your application, you may need to LEDs to be close together. An LED strip inside a plaster cove reflecting against a ceiling may not need LEDs to be close together.

LEDs per meter

LEDs per meter

Closely related to the LED pitch, how many LEDs are on the strip per meter. A strip with 70 LEDs per meter and a strip with 60 LEDs may have the same light output, but one with 60 LEDs may be less efficient as it's driven harder to achieve the same light output.

Wattage per meter (Watts - W)

Power consumption of the LED strip per meter. Power consumption can range from 2-3 watts to over 30 watts per meter and should correlate with the light output.

VIDEO - Are all LED strips created equal?

Light output per meter (Lumens - lm)

The amount of light emitted by a LED strip per meter measured in lumens. Higher powered strips generally emit more light. Beware - Lower quality strips often state the amount of light from the entire reel of LED strip not per meter. One thousand lumens over 1 meter is vastly different from 1000 lumens over 5 meters!

The LED strip lumen output can vary from a few hundred lumens per meter to a few thousand.

Luminous efficiency (lumens per watt lm/W)

How much light do you get out related to the power input? A measure of the quality of the LED strip. Higher quality LED tape should be more efficient, so expect to see a number around 100 lm/W. Efficiency is lower as the colour temperature decreases. A warm white LED strip (3000K) will be slightly lower efficiency when compared to cool white (6000K) within the same manufacturer's range.

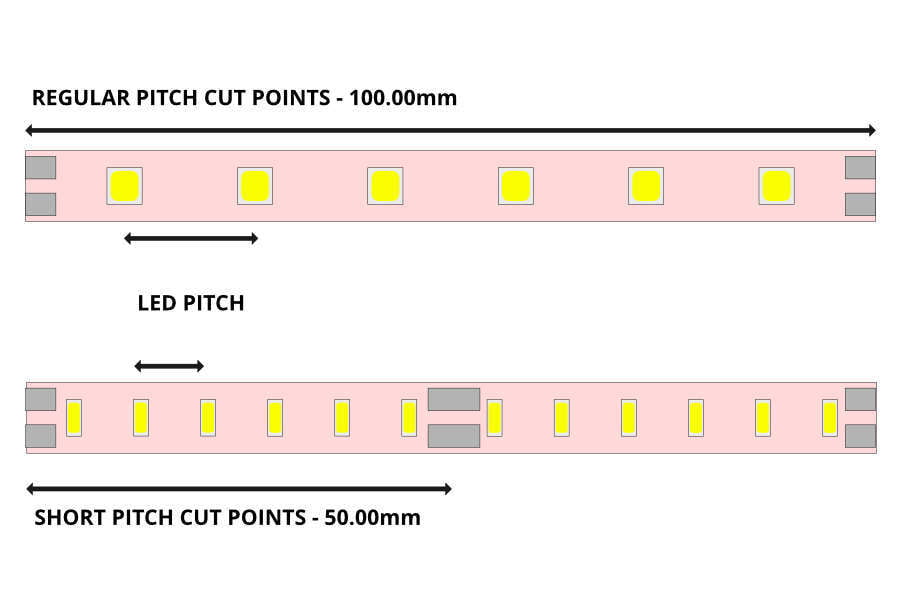

Distance between cut points (No LEDs per smallest unit)

The shortest distance it's possible to cut the LED tape. Cut points are generally closer together if the LED strip has more LEDs per meter and a lower operating voltage. A 24VDC tape usually has 6 LEDs between cut points. A 12VDC strip will usually have 3.

VIDEO - Cutting LED strips

Colour temperature (Kelvin - K)

How warm or cold the light from the LED strip is. Most manufacturers ranges range from 2700K (very warm white) to 6500K (daylight white)

Designers will usually try to match LED colour temperatures with other light sources in the same space.

Beware some manufacturers quote just warm white or cool white. A 4000K cool white and 6000k cool white will be very noticeable.

Colour rendering index (Ra)

How natural colours of objects appear when illuminated by the LED strip. The higher the number, the better. Most LED strips are greater than Ra80 with some specialist ranges available at Ra95. A higher colour rendering index will usually result in slightly lower efficiency. Ra80 is suitable for most general lighting applications. Shops selling clothes or artworks may benefit from Ra95.

Lower quality LED tapes often will not quote a colour rendering index.

Standard deviation of colour matching (SDCM)

LEDs have a slight part to part colour variance when manufactured. The standard deviation of colour matching is a way of measuring this variance. A higher qulaity LED strip will have a lower number, usually less than 5. A low quality LED strip won't mention SDCM. The human eye can't usually detect a varaince less than 3 SDCM . In an application where the LEDs are diffused or mixed (e.g in a cornice) colour varaince between parts should not be an issue. If the strip can be directly viewed, even behind a diffuser, you may detect a colour difference between adjacent LEDs.

Lifespan (hours)

How long the LED tape will last, which can be in the range of 15,000 to over 70,000 operating hours or under 2 years to nearly 8 years of continuous operation. However, LEDs rarely just fail they usually fade away. Operating temperature has a dramatic effect upon LED life and the decrease in light emitted (lumen maintenance).

Higher quality LED strips will usually quote the operating life at a specific ambient temperature or a temperature point (Tc) on the LED strip.

Lumen maintenance

Higher quality LED strips should also state a lumen maintenance figure for the end of life. For example 70% output at 60,000 hours.

Ambient temperature

The range of operating temperatures the LED tape can withstand. Lower temeratures are not usually an issue, but pay careful attention to the upper limit. Higher quality LED strip can usually operate at higher ambient temperatures.

Some manufacturers will also give a range for Tc point - which is a defined temperature measurement point on the LED strip circuit board. This is useful when LEDs are incorporated within an extrusion or lightbox where the ambient temperature inside and heatsinking from extrusions can be considered.

VIDEO - Managing heat from LED strips

Maximum operable length

The maximum length of the LED tape which can be powered in one continuous length or joined together in separate elements. This is limited by the voltage drop along the PCB length and the maximum current which can be carried by the PCB tracks.

24VDC LED tape usually has longer operating lengths.

VIDEO - Connecting to LED strip

VIDEO - What do these LED driver symbols mean?

VIDEO - LED strip soldering jig

SHARE IT

Got a question about this ferrules?