Know how - IP ratings

Words by Gordon Routledge

Video report by Gary Hayers & Joe Robinson

Friday 18th October 2019

SHARE IT

What is the IP rating?

IP66 testing procedure explained... and more!

We visited Lewden Palazzoli's approved test lab to find out about the test procedures used to classify and validate a products IP number.

First IP digit - Objects and dust

| X | X means there is no data available to specify a protection rating. |

| 0 | No protection against contact and ingress of objects |

| 1 | > 50mm Any large surface of the body, such as the back of a hand, but no protection against deliberate contact with a body part |

| 2 | > 12.5mm Fingers or similar objects |

| 3 | > 2.5 mm Tools, thick wires |

| 4 | > 1.0mm Most wires, slender screws, large ants etc. |

| 5 | Ingress of dust is not entirely prevented, but it must not enter in sufficient quantity to interfere with the satisfactory operation of the equipment. |

| 6 | No ingress of dust; complete protection against contact (dust tight). A vacuum must be applied. Test duration of up to 8 hours based on air flow |

Second IP digit - Moisture and Water

| X | X means there is no data available to specify a protection rating. |

| 0 | No protection |

| 1 | Protection against vertically falling droplets, such as condensation, sufficient that no damage or interrupted functioning of components will be incurred when an item is upright. |

| 2 | Protection against vertically dripping water when enclosure is tilted up to 15° off vertical |

| 3 | Protection against direct moisture spray at angles up to 60° off vertical. |

| 4 | Protection against splashing water from any direction, tested for a minimum of 10 minutes with an oscillating spray (limited ingress permitted with no harmful effects). |

| 5 | Protection against low-pressure jets (6.3 mm) of directed water from any angle (limited ingress permitted with no harmful effects). |

| 6 | Water projected in powerful jets (12.5 mm nozzle) against the enclosure from any direction shall have no harmful effects. |

| 7 | Protection against full immersion for up to 30 minutes at depths between 15 cm and 1 metre (limited ingress permitted with no harmful effects). |

| 8 | Protection against extended immersion under higher pressure (i.e. greater depths). Precise parameters of this test will be set and advertised by the manufacturer and may include additional factors such as temperature fluctuations and flow rates, depending on equipment type. |

| 9 | Protection against high-pressure, high-temperature jet sprays, wash-downs or steam-cleaning procedures |

IPX ratings

You may see a product rated as IPX7 or IP5X; this means the manufacturer isn't declaring resistance to dust or moisture. It may be safe to assume a product certified to IPX7 wouldn't allow any dust inside. However, a product certified as IPX5 should not be used in an area with moisture or outdoors.

IP rating do's and don'ts

1.Cable entries

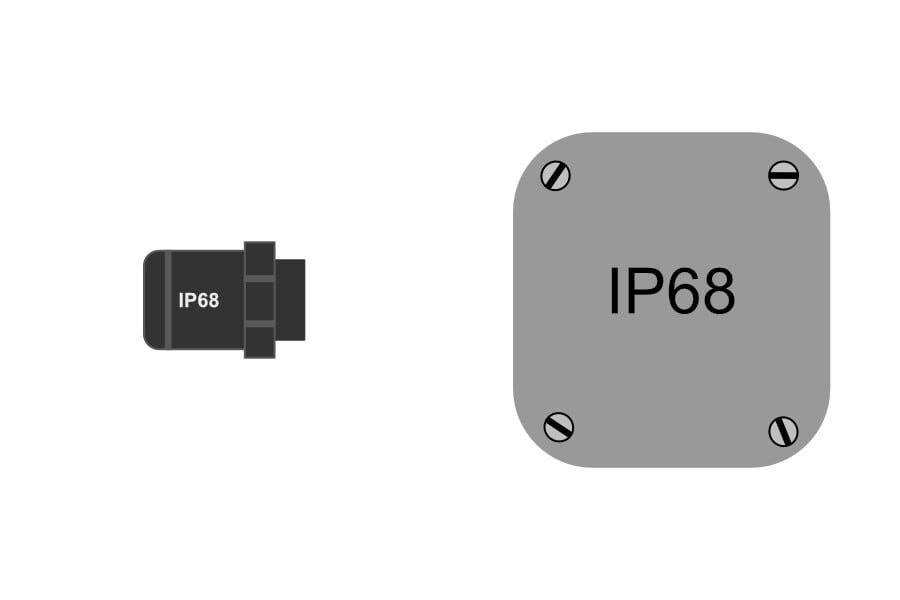

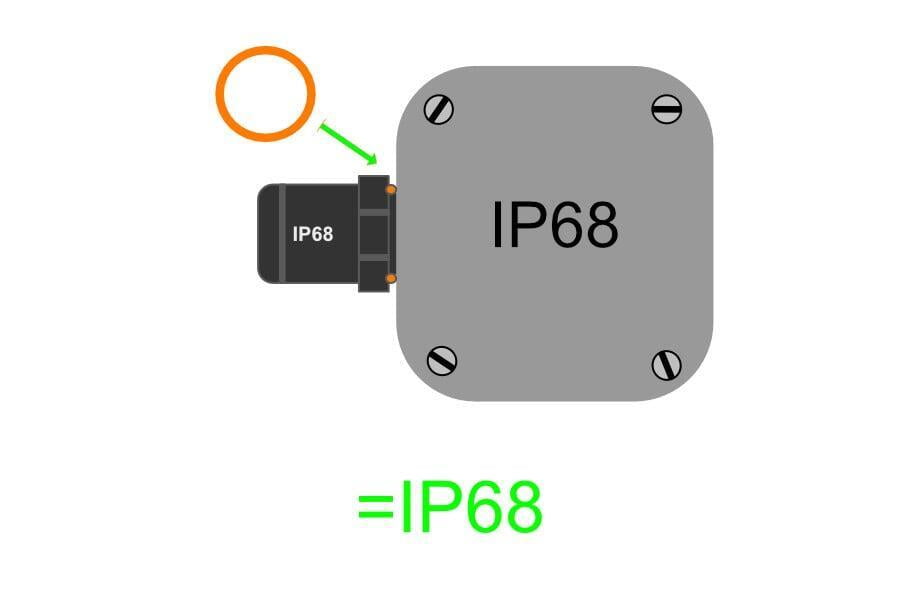

An enclosure rated IP68 combined with an IP68 cable gland can produce a system rated at IP65. Pay careful attention to the junction between gland and enclosure. Lots of cable glands don't include an o-ring for the mating surface.

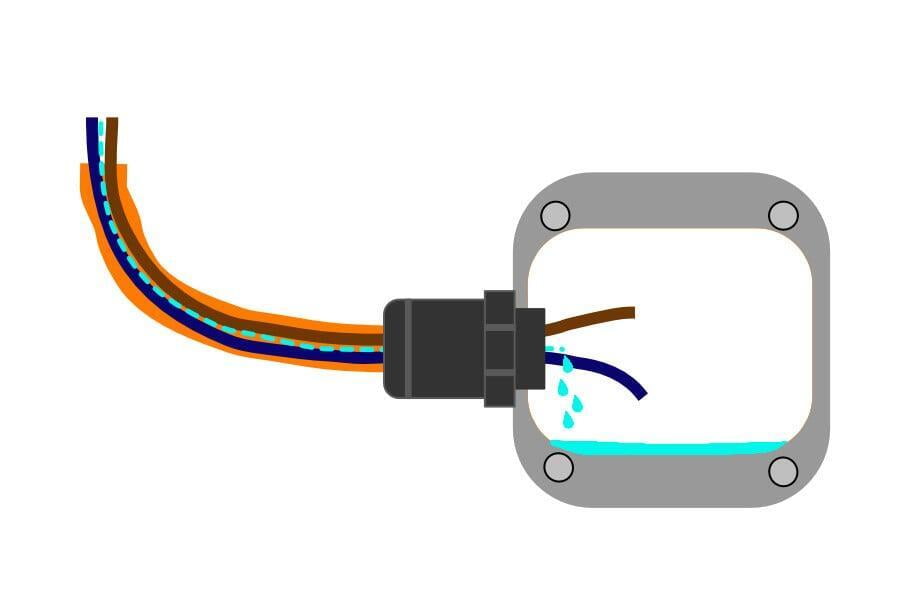

2.Capillary action

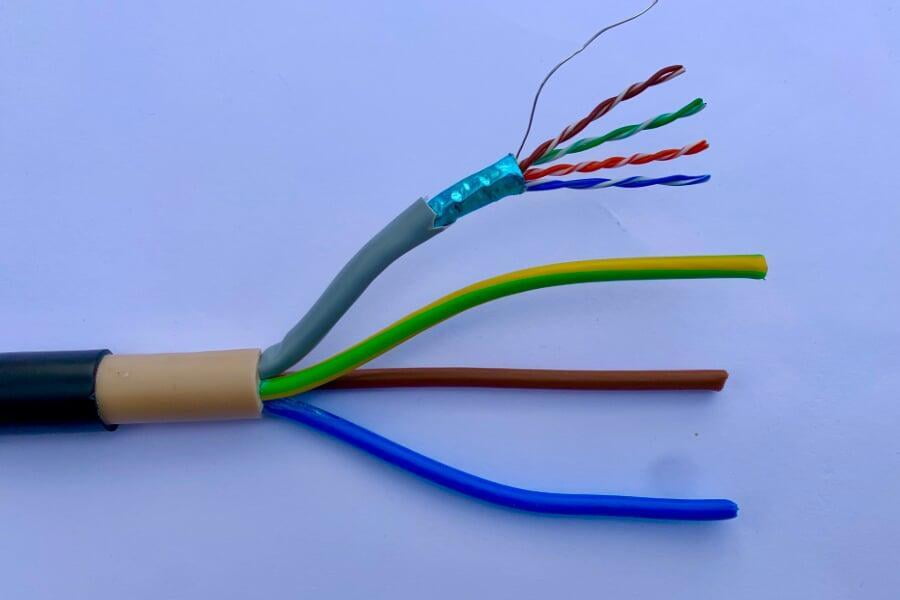

Frequent heating and cooling of enclosures, by sunlight, can cause moisture ingress from capillary action. The air inside the enclosure expands and escapes through tiny gaps between cores of cables. When the enclosure cools, moisture-laden air enters back through the cable and condenses inside. To avoid this, maintain a high IP rating for all cable connections - e.g. resin joints.

3.Higher IP ratings aren't always better

The test for IPX7 (temporary immersion underwater), is very different to IPX6 (high-pressure jets of water) An IP67 enclosure can leak if used with high-pressure jets. A high-quality product will often have multiple IP ratings.

4. IP ratings don't ensure suitability for all environments

IP ratings are what they say, a measure of an enclosures integrity for objects or moisture. The IP code does not imply suitability for other environmental conditions such as saltwater, petrochemicals or resistance to ultraviolet light. A plastic enclosure may become brittle or discolour if exposed to sunlight over months or years.

5.Don't overtighten screws

Pay careful attention to screws and sealing gaskets. The IP rating may depend upon the enclosure screws achieving a specific torque. Over tightening may deform gaskets or the enclosure, particularly enclosures made from plastics.

SHARE IT

Got a question about this product?