How is armoured cable made?

Armoured cable or steel wire armoured (SWA) is one of the most common cables used in the UK electrical industry. Buried in the ground or fixed to factory walls it used in applications from outdoor lighting to power distribution, but how is it made? We visited Doncaster Cables to explore the full process from raw materials to finished cable.

By Gordon Routledge

Thursday 15th August 2019

SHARE IT

Video: We take a tour of Doncaster Cables to reveal the secrets of cable manufacturing.

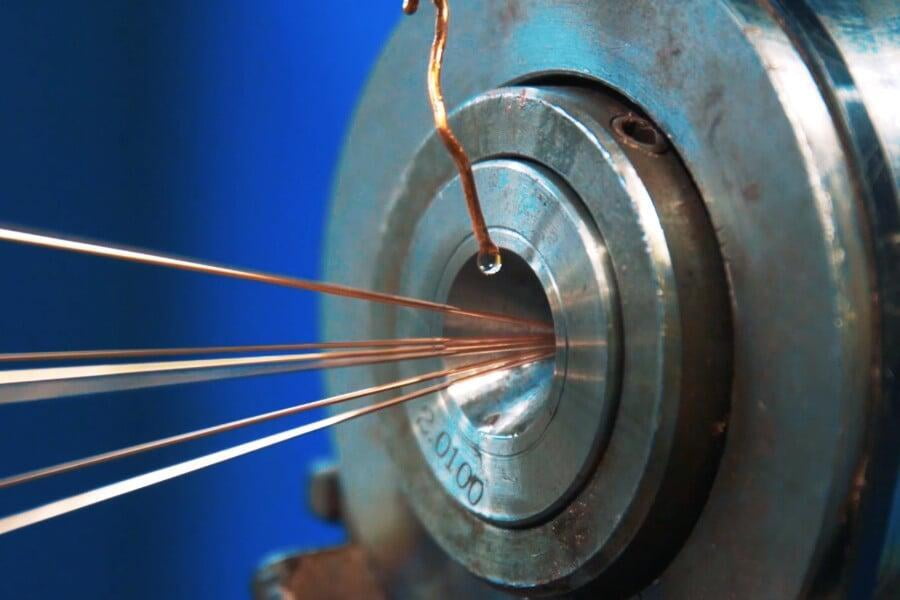

1. Wire drawing

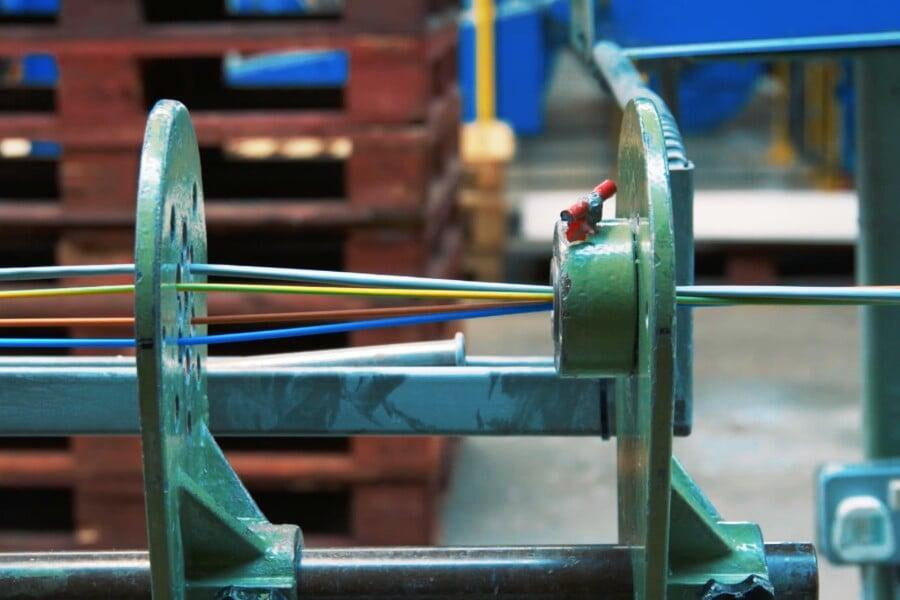

2. Stranding

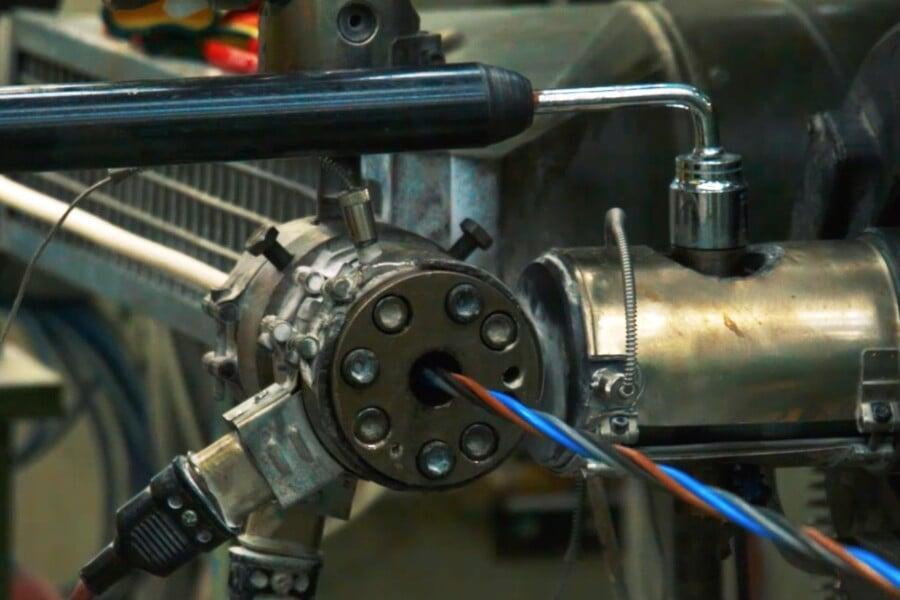

3. Conductor insulation

4. Bundling

5. Bedding

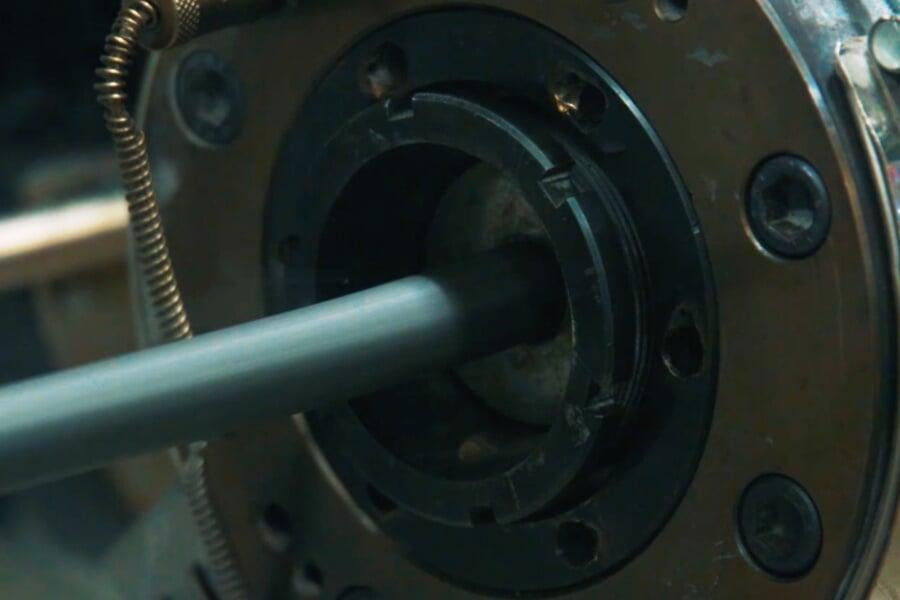

6. Armour

6. Outer sheath

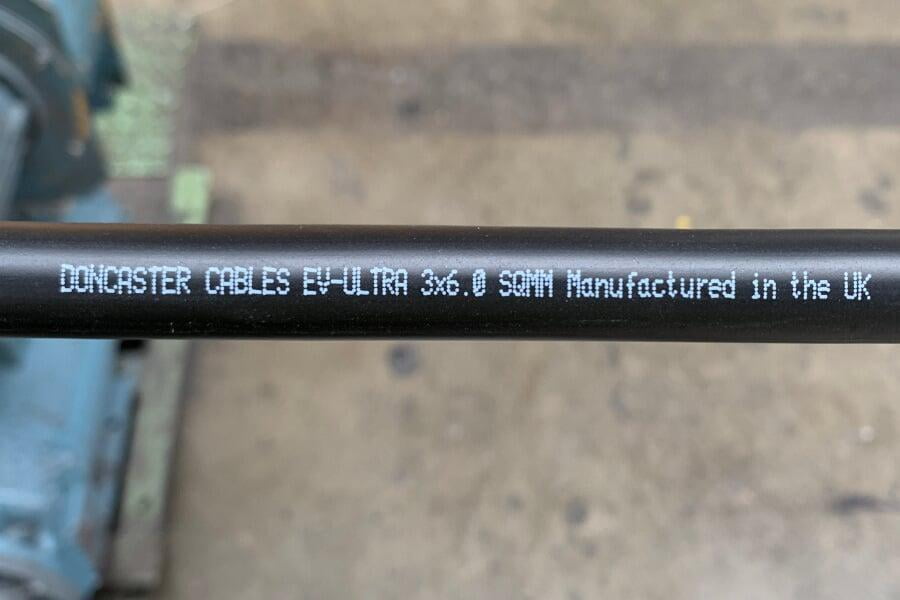

7. Marking

8. Testing