How to install metal conduit like a pro

Metal conduit is used extensively within commercial and industrial electrical installations. This series will guide you through the practical techniques required to design and install an electrical conduit system.

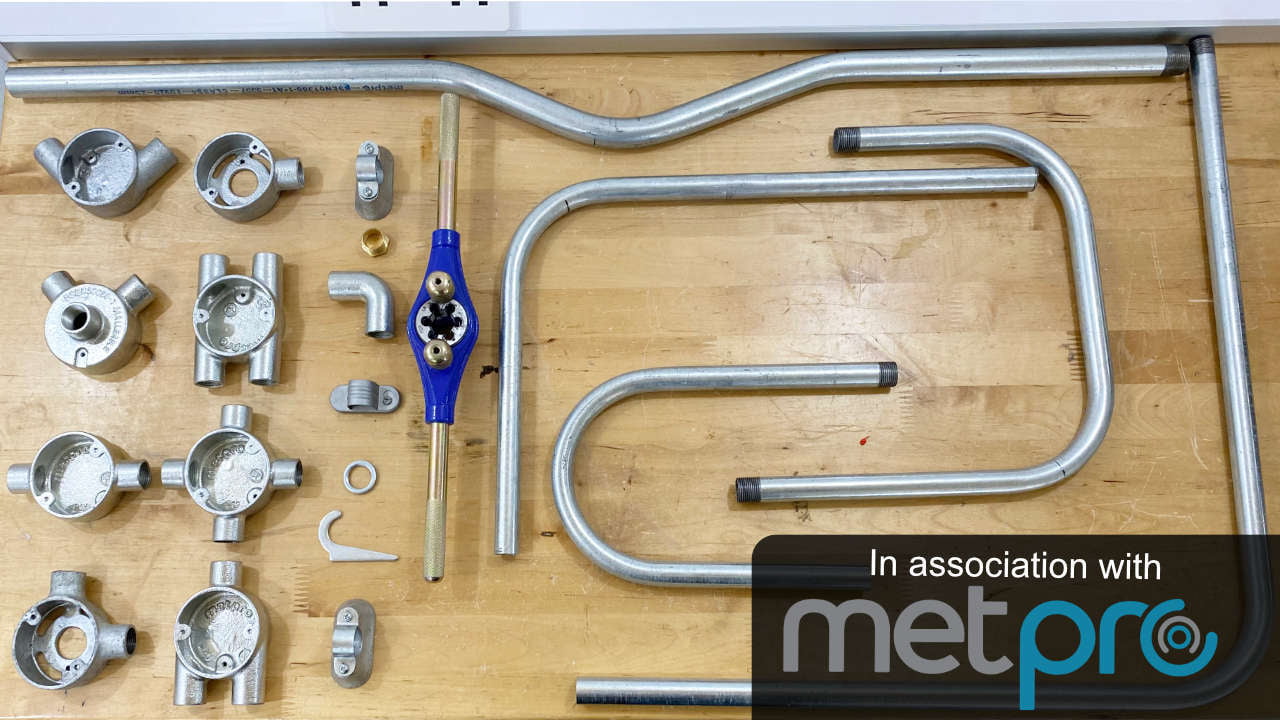

Along the way, we'll explore the range of conduit accessories and the essential tools you'll need.

The eFIXX conduit series is ideal for electrical apprentices aiming to undertake an AM2S assessment. It's also a valuable refresher for electricians who haven't installed conduit for a while, and hence the skills may be a bit rusty (that's a pun).

We'll be using British Standard conduits with nominal dimensions of 20mm and 25mm diameter. If you've discovered this article from the USA, this isn't the same as EMT, British conduit has a thicker wall, and hence you'll notice we use a very substantial conduit bending machine.

Conduit bending machine

Conduit bending machine

An essential piece of kit is required to form and bend a metal conduit. The conduit bender has interchangeable formers to suit the diameter of the conduit formed. They also incorporate a vice used to hold the conduit during the treading process.

Conduit accessories

Alongside the metal tube or conduit are a vast array of different accessories. Conduit boxes, also know as BESA boxes, have standard dimensions. Often UK electrical wiring accessories, e.g. light fittings, are sized to fit straight to a conduit box.

In this video, we've covered the most common conduit boxes, the range of clips to fix conduit to surfaces and adaptors to fit other types of electrical accessories - e.g. switchgear and sockets.

For more complex electrical installations, special boxes and adaptors reduce installation time and handle unique situations.

Conduit threading

Threading the ends of the conduit is the most common way to connect conduit to accessory boxes. This video demonstrates the hand threading procedure using stocks and dies combined with suitable cutting lubricant.